For screen printers, the exposure process can be a point of stress, particularly if you are changing emulsions. The difference between getting a properly exposed screen, and an over or underexposed one can be a matter of seconds with today’s technology. Neither overexposing nor underexposing your screens is good. Underexposure can cause significantly more problems than the alternative. Today we’ll be helping you understand how to avoid underexposing your screens.

What Is Underexposure in Screen Printing?

Exposure is the process of exposing an emulsion-coated screen to a UV light source. This process is intended to harden the emulsion and create the stencil. Underexposure is when a coated screen is not exposed for the proper amount of time.

Different variables can make finding the correct exposure time (referred to as exposure latitude) tricky. Things like mesh count, emulsion type, and your exposure unit all have an impact. As an example, pre-sensitized emulsions (SBQ) have smaller exposure latitudes, while Diazo and dual-cure emulsions have larger latitudes.

How Can You Tell if Your Screen Is Underexposed?

Since an underexposed screen can cause more problems than an overexposed one, there are a few visible signs screen printers can identify to know if a screen is underexposed.

First, if a coated screen feels soft and viscous at the end of its exposure time, that could be a sign that the screen is underexposed. The excess “slime” you feel is the underexposed emulsion that has not properly hardened.

This could also be a sign of too much emulsifier being applied to the screen, although if the coating of emulsion looks normal, it’s probably an exposure issue. It’s important to note that the stencil hardens the print side first, so be sure to touch the squeegee side when checking if a coated screen is properly exposed or not.

Another common sign of an underexposed screen is the stencil washing away with the rest of the emulsifying solution during washout. Depending on how underexposed the screen is, either some of the stencil could wash away, or all of it. An underexposed screen may not always wash away, but it is one of the easier-to-detect signs of underexposed screen printing.

What Are Other Signs of Underexposed Screens?

Some other indicators of underexposed screens include imperfections in the stencil and/or screen. The appearance of slight, transparent dots on the exposed screen is called “pinholing” and is perhaps one of the most obvious indicators of underexposure, although “pinholing’ can also be caused by other factors.

Other defects that are caused by underexposure are sawtoothing and scumming. Sawtoothing describes an irregular, undefined printing edge caused by the exposed emulsion, not hardening enough, and thus having weak washout resistance. Meanwhile, scumming is when a thin layer of emulsion blocks the open areas of the mesh, rendering the stencil useless.

Scumming is harder to see than the other issues. Unfortunately, it’s a common problem in the exposure process. All these signs cause delays in your process and can lead to slowdowns, redoes, or worse, faulty orders. Proper exposure avoids these problems.

How to Correctly Expose Coated Screens

The most common methods for getting correct exposure are exposure calculators and step tests, but both have their pros and cons. Exposure calculators involve taking two films, one with a variety of images, halftones, text and lines and another with gradually darker shades of ink. By combining the two films, an exposure calculator shows you how your emulsion will look based on the amount of light passing through.

Each shade functions as different exposure times, filtering out different amounts of light during exposure. In the end, you’re left with several different images, ranging from underexposed to overexposed, and several factors next to each one.

Screen printers plug these factors into a calculation, and the number they get is the recommended exposure time. Changing even one of these variables will mean doing the exposure calculation process over again.

Another method for manually finding the right exposure time is with a step test. The general idea of a step test is to expose a segmented screen repeatedly in small increments to gradually find the correct exposure time.

While both exposure calculators and step tests can help determine proper exposure time, both are painstaking in their own way and take time. But with screen printing technology continuously evolving, there are now faster, more efficient ways to test for exposure time.

Choosing the Right Screen Printing Exposure Unit

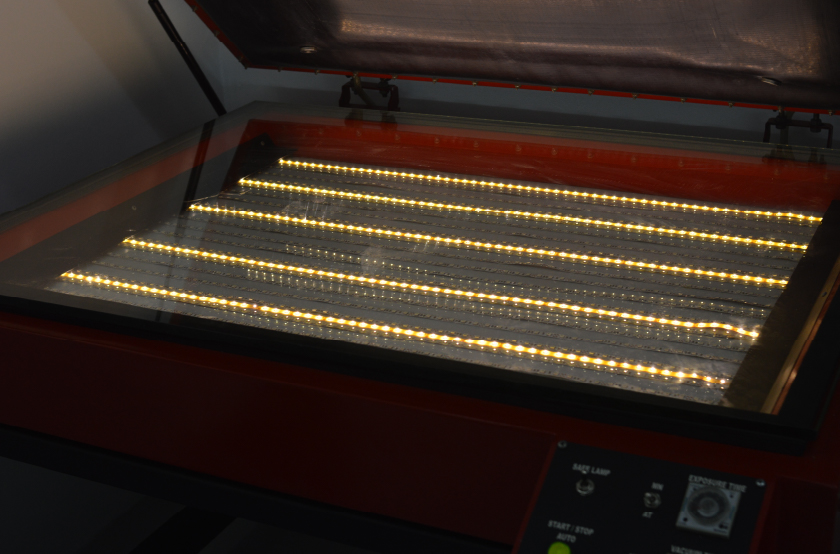

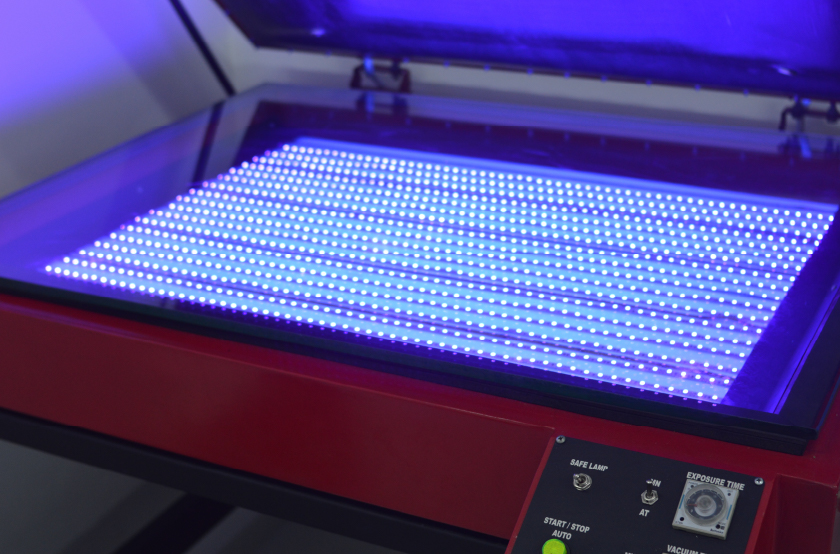

The type of exposure unit you use matters significantly. Different exposure units use different light sources with different exposure levels. EXILE Technologies’ V-Lux was designed for computer-to-screen (CTS) systems, but its UV-LEDs produce the ideal wavelength to quickly expose most any type of coated screen.

Thanks to its full panel array of UV-LEDs, the V-Lux also has a longer lamp life, lower energy consumption, and cooler operating temperatures (between 50-90°F). Best of all, over time, the V-Lux screen printing exposure unit will maintain a steady output of power, so it will perform just as well years from now as it does today.

The V-Lux typically can expose SBQ emulsions in 8-10 seconds (due to their low emulsion latitude), and both Diazo and dual-cure emulsions in 15-18 seconds. Compare this to other exposure units, which can have exposure times ranging anywhere between 1½-3 minutes for Diazo and dual-cure emulsions, and around 30 seconds for SBQ emulsions (and even this figure would be considered quite fast).

Of course, there are always outliers thanks to factors like mesh count and emulsion thickness, but the above time frames are consistent. So, to keep your operation flowing smoothly, the V-Lux features both fully automatic and manual operation settings, as well as 15 programmable preset slots. This way, you can adjust to any differences as they come up and avoid delays.

The V-Lux exposure unit also utilizes integrated rails to make sure screens placed inside are properly distanced from its light source every time, which removes another potential variable in the exposure process. Many of the problems caused by underexposed screens can be avoided with the right knowledge and technology, which is what the V-Lux screen printing exposure unit offers screen printers.

EXILE Technologies’ Expertise

EXILE Technologies has been providing screen printers with innovative imaging solutions, specialized products, and reliable support for over 30 years. If you’re interested in investing in the V-Lux screen printing exposure unit and eliminating underexposed screen printing for good, contact us today to get started.