Screen printing is a wonderful and ancient printing process used to create vibrant, durable prints on a variety of materials, but, like most things, it isn’t infallible. Every now and then, a print may not go as planned, but the good news is that most of these issues can be easily resolved. In this blog, we’ll discuss common screen printing problems and provide troubleshooting tips to ensure your prints come out perfectly every time.

Common Screen Printing Problems and Their Solutions

Ink Spreading and Viscosity Issues

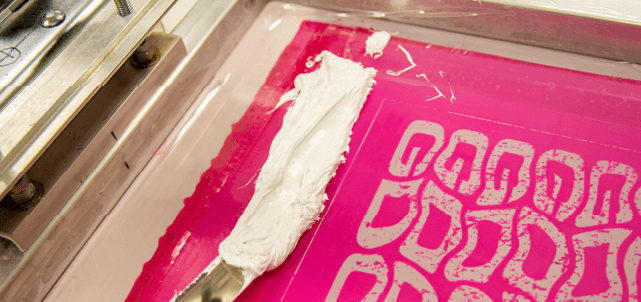

One of the most common problems screen printers encounter is ink spreading. This occurs when the ink does as suggested, but spreads beyond the desired image area and causes the print to come out blurry, messy, or bleed through the material. While inconvenient, the issue can be easily resolved by ensuring the ink is thick enough for the project and that the squeegees haven’t dulled down. Regularly checking the ink’s consistency and ensuring screen tension is properly set can help control the ink flow and improve the print quality.

Screen Tension

Proper screen tension is essential to make sure any screen-printing project proceeds smoothly. A loose screen can cause registration problems, where different colors in the print do not align correctly. Inconsistent screen tension can also lead to uneven ink application. Use only properly tensioned screens to ensure sharp, well-defined edges and consistent prints.

Mesh Count

Mesh count also has the potential to cause issues. A detailed print can appear choppy and uneven or result in a “blowout” if the mesh count is too low, resulting in a poor imitation of the desired image. Conversely, if the mesh count is too high, the print may have poor ink coverage due to restricted ink flow. Both of these problems stem from having an incorrect mesh count. To avoid this, ensure you’re using the right mesh count before the printing process begins. Finding the right balance is essential for achieving optimal results and ensuring your prints come out clear and accurate.

Stencil and Exposure Problems

Proper exposure is key to creating a durable and high-quality stencil. Underexposed screens can result in weak stencils that break down quickly during printing, which leads to loss of detail and premature stencil failure. On the other hand, overexposed screens can make it difficult to wash out the image area, resulting in clogged screens and loss of fine details. To avoid this, use a calibrated exposure unit and follow guidelines for exposure times. By conducting exposure tests, you can determine the optimal exposure time for your specific setup and ensure that your screens are neither underexposed nor overexposed.

Additionally, ensure the stencil material is compatible with your emulsions and exposure methods. If the wrong type of emulsion is used, this can lead to poor stencil durability and difficulty washing out the image area. Thoroughly mix the emulsion and apply it evenly to the screen to create a strong, consistent stencil capable of withstanding multiple print runs.

Registration Issues

Registration problems occur when the different layers of a multicolor print do not align properly. This can occur due to various factors such as screen movement, improper screen tension, or inaccurate setup. Ensuring the screens are tightly secured and using registration marks can help maintain alignment throughout the print run. While regular press maintenance can prevent these issues, a more efficient solution would be to rely more on a pre-registration system from the press manufacturer and use Computer-to-Screen (CTS) technology, which offers precise system matching to those on the press to minimize these problems

Improving Print Quality with Technology

Throughout this blog, we’ve consistently mentioned how manual adjustments and troubleshooting can address many common screen printing problems. However, it’s important to address the many advanced solutions that technology offers. Computer-to-Screen (CTS) technology is a prime example, as it offers precise control over screen exposure and registration, significantly reducing the margin of error.

Accurate Registration

CTS technology automates the screen exposure process to ensure each screen is perfectly aligned. This eliminates potential registration issues that can be caused by manual setup errors and results in consistent, high-quality prints.

Increased Efficiency

Production delays can stem from various screen printing problems, including prolonged setup times and frequent troubleshooting. By streamlining the screen preparation process, CTS technology reduces setup times and increases production efficiency. This allows screen printers to spend less time calibrating for errors and more time printing.

Contact EXILE for Superior Pre-Press Technologies

At EXILE Technologies, we understand the complexities of screen printing and the importance of overcoming common challenges to achieve the best results. That’s why EXILE offers our advanced CTS system to address key issues such as registration, exposure, and production delays, providing screen printers with reliable and efficient solutions.

By integrating cutting-edge technology into your screen printing process, you can easily minimize common screen printing problems and elevate your print quality. Whether you’re dealing with ink viscosity issues, mesh count dilemmas, or registration troubles, EXILE Technologies offers the tools and expertise you need to succeed.

For more information on how our CTS systems can revolutionize your screen printing operations, visit our website and explore our range of innovative products. Join the growing number of screen printers who trust EXILE Technologies.