Starting a professional screen printing business is an exciting venture, but having the right tools is key to achieving the results you want. Whether you’re just beginning or looking to upgrade your setup, understanding the essential and advanced equipment needed for screen printing can help you create high-quality prints efficiently. In this blog, we’ll explore the must-have tools for beginners and delve into specialized equipment for experienced printers ready to take their craft to the next level.

Basic Equipment

Starting a screen printing business requires assembling the right tools to ensure your designs come to life with precision and quality. This list highlights the most essential equipment for beginners, laying the foundation for a successful and efficient screen printing operation.

Screen Printing Press

At the heart of any screen printing setup is the press, which holds your screen in place and ensures even pressure when applying ink. Beginners typically start with a manual press with one to four color capabilities, while businesses with higher output needs may opt for automatic presses later. Look for sturdy construction and adjustable clamps to get consistent results.\

Screens and Frames

Screens are the foundation for creating your design. Made with mesh stretched over a frame, they come in various mesh counts, which determine the level of detail you can print. Lower mesh counts are great for solid color designs made with larger areas of coverage, while higher counts suit intricate detail. Aluminum or wood frames are common, with aluminum being more durable, more reliable, and more consistent for long-term use.

Emulsion and Exposure Unit

To transfer your design onto a screen, you’ll need a photosensitive emulsion and an exposure unit. After coating your screens with emulsion and processing them appropriately, the exposure unit uses UV light to harden the areas of the screen that are not covered by your design. Once exposed, you simply wash out the unexposed areas of the screen, leaving a stencil ready for printing. Exposure units are primarily made up of UV lights. For very basic setups, sunlight has been used as a budget-friendly option.

Squeegees

Squeegees are essential for spreading ink evenly across the screen to transfer your design onto the substrate. They come in different sizes, blade shapes, and durometers (hardness levels) to suit various printing needs. A medium durometer squeegee with a comfortable handle is a versatile option for beginners.

Ink

Screen printing inks come in various types, such as plastisol, water-based, and discharge inks. Plastisol ink is beginner-friendly, durable, and easy to work with, making it a popular choice. However, water-based inks are an eco-friendly alternative, offering a softer finish that works well on lighter fabrics.

Substrates (Printing Materials)

Your substrates are what you’re printing on—most commonly t-shirts, hoodies, or tote bags. Choose high-quality materials that match your ink and design requirements. For apparel, 100% cotton is ideal for vibrant prints, while blended fabrics may require specific ink types for optimal results.

Drying and Curing Equipment

Proper curing ensures that your designs are durable and don’t wash off. For beginners, a flash dryer or heat gun can work for small batches. Since these are not ideal, investing in a conveyor dryer is essential for consistent results and higher volumes. These tools apply heat evenly to cure ink thoroughly.

Washout Booth and Cleaning Supplies

After printing, screens must be cleaned for reuse and reclaimed for new designs. A washout booth provides a designated space to rinse ink and emulsion residue. Pair this with a high-pressure hose, screen cleaning chemicals, and rags to maintain your equipment and extend its lifespan.

Artwork and Design Software

Screen printing starts with a design, and using software like Adobe Illustrator or CorelDRAW lets you create or prepare artwork for printing. These programs allow you to create vector files, raster files, and separations necessary for multi-color designs, ensuring crisp and professional results.

A Reliable Workspace

Don’t overlook the importance of your workspace! A well-ventilated, well-lit area with ample space for organizing your tools, supplies, and drying racks ensures efficiency and safety. Setting up a clean, organized station also improves productivity and workflow.

With these essentials, you’ll be equipped to start your screen printing journey and create quality printed products that stand out.

Advanced Equipment and Machines

As your screen printing business grows, investing in advanced equipment can enhance efficiency, expand your capabilities, and deliver higher-quality results. This list highlights the tools and technologies that can elevate your operation, from automation to cutting-edge imaging systems like CTS and DTM printers.

Computer-to-Screen (CTS) Imaging Systems

CTS systems eliminate the need for traditional film positives by digitally transferring artwork directly onto the emulsified screen using a high-precision laser or inkjet technology. This advanced technology reduces setup time, enhances registration accuracy, and eliminates film costs, making it ideal for high-volume or detailed designs. By streamlining the screen preparation process, CTS improves workflow efficiency and minimizes waste.

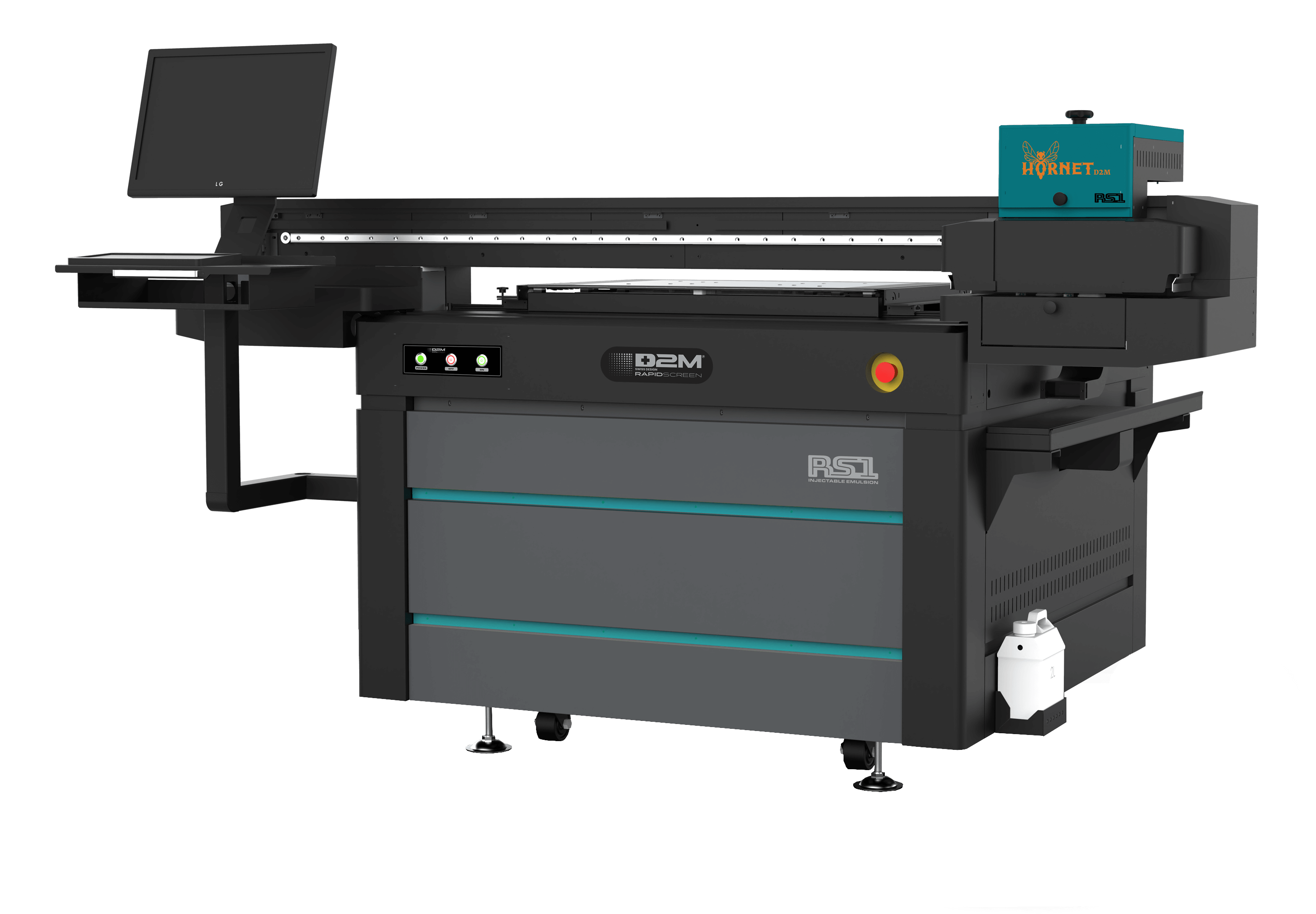

Direct-to-Mesh (D2M) Printers

A D2M printer streamlines the screen preparation process by digitally printing the emulsion directly onto the mesh, bypassing the need for traditional film positives, manual transfers, or masks. This advanced technology improves registration accuracy and reduces processes and process times, eliminating many consumable and process costs present in screen preparation. Like CTS, D2M is an ideal choice for many screen printing operations. With a D2M system, you can achieve great detail and enhanced production efficiency, giving your business a competitive edge in the screen printing industry.

Automatic Screen Printing Press

Upgrading to an automatic press dramatically increases production capacity while ensuring consistent results. These screen printing machines handle multiple colors and prints with minimal manual input, reducing operator fatigue and allowing for greater precision. Automatic presses are especially beneficial for businesses scaling up to meet large orders, multiple orders, and tight deadlines.

Conveyor Dryer with Advanced Temperature Controls

For professional-grade curing, a conveyor dryer with precise temperature controls is essential. Advanced models include adjustable belt speeds, even heat distribution, and infrared curing technology to handle different ink types, including water-based and discharge inks. These dryers ensure consistent curing, improving the longevity and vibrancy of your prints.

Pre-Registration Systems

Advanced pre-registration systems help streamline multi-color printing by aligning screens with pinpoint accuracy before they reach the press. These systems save time during setup and reduce material waste, making them invaluable for detailed, multi-layer designs that require perfect alignment.

Screen Cleaning and Reclaiming Systems

Automating the cleaning and reclaiming process with dedicated machines saves time and reduces the effort required to clean screens. These systems use pressure, water, and cleaning agents to efficiently remove ink and emulsion, extending the life of your screens and ensuring they’re ready for reuse. Some models also include filtration systems to manage waste and meet environmental standards.

Exposure Unit with LED Technology

Advanced LED exposure units provide faster and more efficient screen exposure compared to traditional UV models. They produce sharp detail and potentially reduce the risk of overexposing or underexposing emulsion.

Specialized Heat Presses

Heat presses are essential for curing specialty designs, like foil transfers, vinyl, or puff ink effects. Advanced heat presses include programmable temperature and pressure settings to accommodate different materials and effects, ensuring uniform application for a polished finish.

Artwork Separation Software

Advanced software for color separations and halftone processing ensures your designs translate perfectly to screen. Programs like Separation Studio or T-Seps, to mention a couple. create accurate screen files for multi-color prints, saving time and ensuring a professional-quality outcome.

Screen Racks and Storage Systems

Efficient storage solutions, like multi-tier screen racks, are crucial for maintaining organization as your production volume grows. Advanced racks often include adjustable shelves, protective coatings to prevent screen damage, and space-saving designs to optimize your workspace.

Specialty Printing Attachments

Attachments such as sleeve platens, hat platens, or all-over print pallets allow you to diversify your offerings and print on unique substrates. These add-ons expand your business potential, catering to custom apparel markets and promotional items.

Investing in advanced equipment like CTS and D2M systems not only improves efficiency but also opens doors to new opportunities, ensuring your screen printing business stays competitive and capable of delivering exceptional results.

Screen Printing with EXILE Technologies

Building a screen printing operation requires a significant investment in both basic and advanced equipment, making it a costly endeavor for many. For those who only need a few custom items or a single high-volume order or cannot afford all of the equipment needed for screen printing businesses, partnering with a skilled screen printing business is often the most efficient and cost-effective solution. Experienced professionals have the tools and expertise to deliver exceptional results without the upfront costs or learning curve.

At EXILE Technologies, we provide innovative imaging solutions like CTS systems that empower screen printers to achieve unmatched precision and efficiency. Whether you’re starting a business or scaling up your operation, our advanced equipment and expert support are here to help you succeed. Contact us today to learn more about our cutting-edge screen printing technologies.