When does adding a CTS machine to your screen printing operation makes sense?

You’ve heard all the benefits that a computer-to-screen (CTS) system can offer your screen printing shop, but when do you know if the time is right to make the investment to add the equipment? Prior to the COVID-19 pandemic, the average barometer for adding a CTS machine was when a shop had at least two automatic presses. Since COVID-19, things have changed.

Because of the labor shortage, during which many people stopped wanting to work for minimum or smaller-wage jobs, screen printers have been forced to look at their operations and see whether automating in certain departments is the right decision. Part of that automation decision includes adding a CTS machine. Today, whether a shop is ready depends more on the number of screens produced daily rather than the number of auto presses. Even manual shops can justify adding CTS if the number of screens is around 15-20 per day, whereas, before COVID-19, it was 40-50 screens per day.

This drop in the number of screens (or frames) per day is based on three things: labor, time, and monetary savings. Each shop is different, and there are no set benchmarks for knowing when a shop is ready to automate. One shop may go computer-to-screen to save on labor costs or to make up for labor shortages, whereas another may be spending too much time setting up their presses, thus, spending more money in the long run and often requiring the shop to set its prices higher. This affects its competitiveness in the local and national marketplaces. Press setup time is a primary advantage of adding a CTS machine.

WHAT’S MY COST?

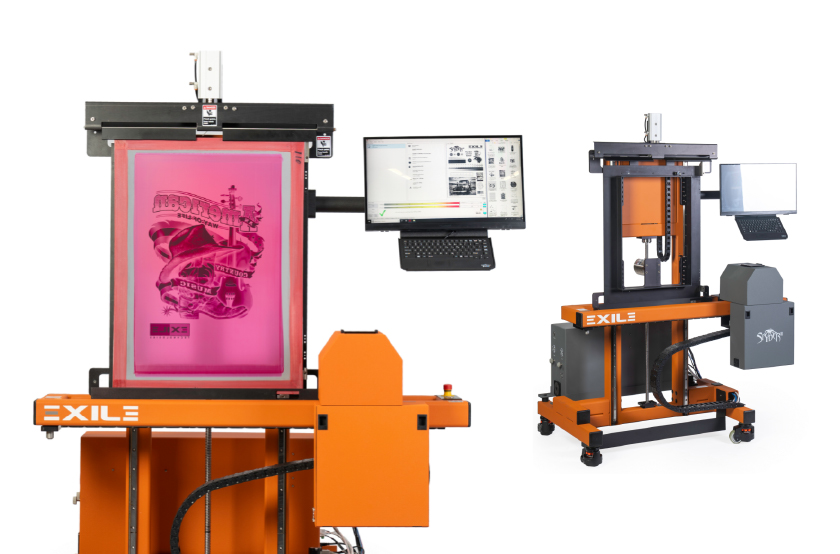

The general initial investment for a Spyder CTS machine is between $55K and $65K, depending on the machine’s upgrades. Often, the machine is sold with an LED exposure unit, which gives an advantage in savings and production accuracy in eliminating pinholes and the like. When it comes to ROI, it depends on the number of screens per day the shop is doing. If you are producing an average of 20 screens, it takes about 18 months to get the money back on your investment. Some lower-volume shops get an ROI in 24-36 months.

GETTING TRAINED AND PRINTING

While adding a CTS machine to your operation saves time and money in the short term, there is a small learning curve that must be overcome. Training is offered by EXILE Technologies as part of the installation cost, which is about $1,800. With that, we plan on being on-site with technical trainers for three days to get the shop owner and staff up and running. On the first day, our team will ensure the machine is installed and ready to go. Typically, by the end of the first day, the staff can begin printing. By the end of day two, the shop is in production with their new Spyder.

On the second day, we spend time training in the art room. That’s because the CTS machine brings the art and screen rooms together as opposed to treating them as separate entities the way they are when a shop isn’t CTS driven. You’re no longer putting film on screens, so it’s up to the artist to position the artwork in the correct location. EXILE goes in and sets up templates for layouts involving a full-frontal design, left-chest, sleeve, etc. If you’re using film and doing a four-color left-chest design, you’re going to be worried about wasting film for a four-by-four-inch design. On computer-to-screen, you can put that left-chest design on an 18 x 22-inch template because you’re not worried about wasting film. We put in guide marks, and the artist just moves that left-chest logo into position in the right location. The artists should be able to pick up on the process quite easily.

By the end of the second day, we’re printing large jobs with the team. The artist sends jobs to the screen room; they get on the press more quickly and production increases while labor is lessened. Finally, on the third day, we observe and let the staff run the machine and their respective departments. We’re there to answer any questions and work with them on any challenges they might encounter. The service and support don’t stop with the sale of the machine; EXILE is with the client every step of the way before, during, and after the machine is sold.

To make sure a shop is ready to make the leap into investing in a CTS machine, EXILE sends sales staff to the shop to look around and make sure the environment is correct prior to installation. You want to make sure there aren’t things like a washout booth right next to where the machine will go, so it doesn’t get damaged by water. Also, the screen room has to have a good ethernet jack because the Spyder uses the shop’s network for the artists to send jobs from the art room to the screen room. Without one, the artist and machine operator must take the job on a thumb drive from department to department, slowing things down. Additionally, compressed air is a must! It’s very important that a shop is clean to keep dust off as well, so these are things we are looking for prior to installation.

Often, suggestions are made six to eight weeks prior to the CTS machine’s delivery. Sometimes the EXILE executive will suggest a wall be put between the machine and other equipment on the production floor. Often it can be done using those plastic streamers to separate rooms — those will suffice to make things clear, clean, and easy.

LONG LIVE CTS

So, what is the life expectancy of the machine? The machine itself will not need to be replaced for years, but some components will need attention and occasional care. Usually, the printhead will need to be replaced every three to five years. There are, however, a lot of factors that go into the life of a printhead, some of which are beyond EXILE’s control. This relates back to how clean the environment is and how well the machine is maintained. So, you can expect to pay a few thousand dollars to replace a printhead and ink-feed system, but that can be amortized if the machine is well-maintained and used correctly.

It’s important to note this because the CTS machine can be the single point of failure for a screen printing shop if it goes down, which is rare. If it does, it usually is because of environmental failure. Everything on the production floor stops if the jobs can’t get to presses from the CTS machine. That’s the reason EXILE is so committed to tech support. If we need to be there and our tech team is tied up, even our salespeople come out to your shops to work through challenges. EXILE is the only computer-to-screen company that designs, develops, and manufactures its own CTS machines. That means experts are ready at a moment’s notice to help get the situation resolved more quickly than our competitors.

Adding a computer-to-screen machine to your screen printing shop is a financial commitment, but one that will pay off quickly if done correctly. Not only are you saving time, money, and labor, but you also are being more environmentally friendly and getting an ROI on an important piece of equipment that will change the way you do business.