Apr 12, 2024 | Industry News, News Hub

The new Spyder III (left) alongside the Spyder II at Fresh Air

Exile Technologies has installed the first Spyder III computer-to-screen at Fresh Air.

The London-based garment decoration shop has been using the Spyder II system since 2018 but needed a supplementary system to cope with demand – the company has nine automatic screen printing presses and the capacity to print 40,000 garments each day, and can need 200 or more screens a day during busy periods.

“The DLE [direct laser exposure] systems look great on paper but cannot match the Spyder systems for imaging speed, even when you use the manufacturer’s recommended fast exposure emulsions, which carry a price premium,” explained owner Lee Craze.

“We were very happy with our existing emulsion choices and the new Spyder III gives us the ability to run higher screen rulings to boost our stencil image quality.”

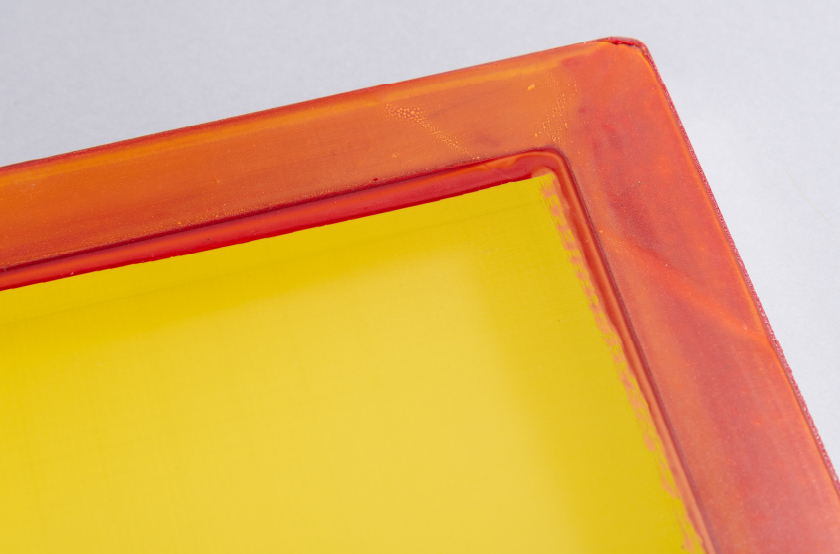

The Spyder III was officially launched in the UK in February and received its mainland European debut at Fespa Global Print Expo in March. It has a new 1,200dpi Xerox industrial print head and can be used with any type of emulsion without compromising imaging speed, promises Exile.

It can produce a typical T-shirt screen stencil in 60 seconds or less, and can come with tri-lock mechanical registration systems, or an optional MHM-compatible pin registration.

“Artwork is applied and positioned digitally, with 0.01% accuracy, directly on to a coated screen,” said Exile.

“This eliminates the need for manual and labour-intensive film registration, thereby streamlining the entire screen preparation process. The combination of mechanical registration and digital image placement eliminates any human error associated with manual film placement and translates into significant reductions in press set-up times and dramatic increases in screen-room productivity.

“The stencil is printed directly onto a coated screen and after imaging the screen is ready for immediate exposure on the optional V-Lux UV-LED exposure system, without the need for a glass or vacuum. Pin-holing is therefore completely eliminated and because the stencil is ‘bonded’ to the emulsion, there is no undercutting of the stencil, so small highlight detail is retained. After exposure the water soluble wax washes off quickly and easily along with the unexposed emulsion.”

www.exiletech.co.uk

www.freshair.co.uk