Direct to garment (DTG) printing is a fairly new concept that was made commercially available in the 1990s. Since then, direct to garment printing has come a long way and continues to be a leader in the printing press business. For those who may be new to the print industry, you may be wondering, “How does DTG printing work?” The process is simpler than you might think and differs from direct to screen printing quite a bit.

How does it work?

Graphics are printed directly onto the desired garment by machine. In fact, a DTG printing machine works similarly to how your inkjet printer at home or in the office would, but instead of paper, an article of clothing or fabric is utilized instead. By using a digital printing method, DTG printing takes the ink and jets it onto the fabric in a matter of minutes. Direct to garment printers can be used on t-shirts, sweatshirts, posters, banners, and so much more! Most DTG printing machines require RIP software.

It is extremely important that you use a t-shirt that has had pre-treatment added to it prior to starting the direct to garment printing process. You run the risk of a lower quality print if you skip out on this crucial step. Next, designs will often start with a white ink base to go underneath the entire artwork in order to make it pop, so set up your DTG machine and print the white base on. You can now move on and start printing your CYMK colors. Unlike DTS printing technology, you do not have to separate your colors and print them one at a time. Finally, you cure your t-shirt and let it set.

That’s it! Your t-shirt should have high-quality artwork placed exactly where you have designated it to print.

Where did DTG printing start?

The first DTG printer, named the “Revolution,” hit the market for commercial use in 1996. A man named Matthew Rhome was able to invent and acquire a patent for this particular DTG printer granted to him in 2000. When production ended for the Revolution model, Rhome decided to create another DTG printer and present it at a SAGA convention in 2005. This printer would become the first Brother DTG Printer available.

Today, Rhome is widely known as the founder of the DTG printing industry and he currently works for Epson America in the DTG Business Development department.

How is DTG printing different than DTS printing?

Direct to screen printing is done in layers—depending on the number of colors needed—by pressing ink through screens manually to get the design to “print” onto the t-shirt. Direct to screen printing is a classic method of printing and requires more time and labor. However, direct to screen printing can also produce vibrant prints that display well on a number of different fabrics.

Get a more in-depth look at the differences between DTS and DTG printing here.

Will DTG printing work for my business?

Let’s take a look at some of the key factors that determine whether DTG or DTS printing is a fit for you and your business.

Project size: How many garments need to be printed? Whether it is 50 or 500 makes a huge difference. DTG printing works best with smaller projects. Taking on large orders is not cost-effective for this method of printing.

Artwork: DTG printing makes customized t-shirts possible. Since there is no color limit for DTG printing, complex designs and forms of other artwork can be successfully printed per your customer’s request.

Affordability: There is a little upfront cost to get into DTG printing technology for your business.

Our top picks

We offer a few DTG machines that can get the job done with superior quality including:

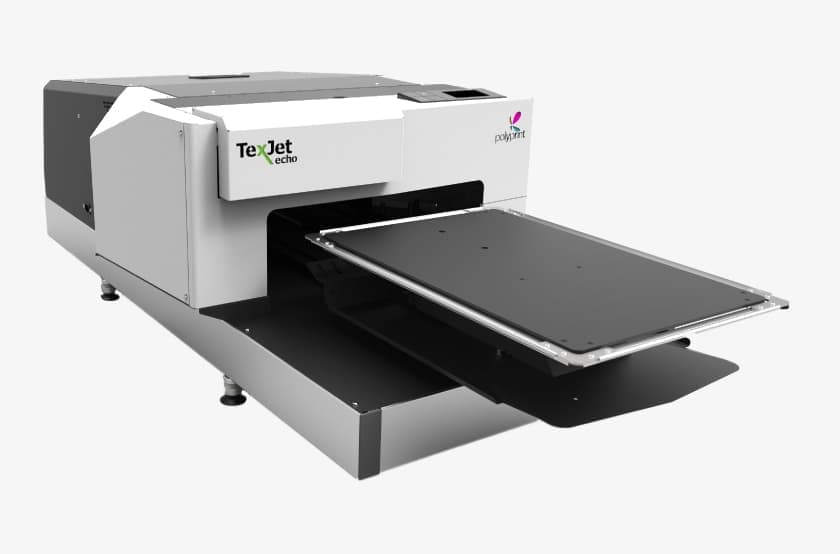

With the TexJet® echo, you get a DTG printer that can print on dark garments efficiently, lowering ink cost. Enhance your creativity and explore apparel decorating on a number of garments including pockets, leggings, hoodies, bodysuits, and more!

TexJet® echo specs

Max Print Area 16.14×23.625in

Printable Textiles Cotton, polyester, cotton/polyester blends, linen, viscose, leather, and more

Print Resolution 720×720, 1440×720, 1440×1440 dpi

Multiple combinations possible (ie. 1440×1440 White x 720×720 CMYK)

Print Head Type Piezoelectric DOD, 8 channels, 180 nozzles per channel

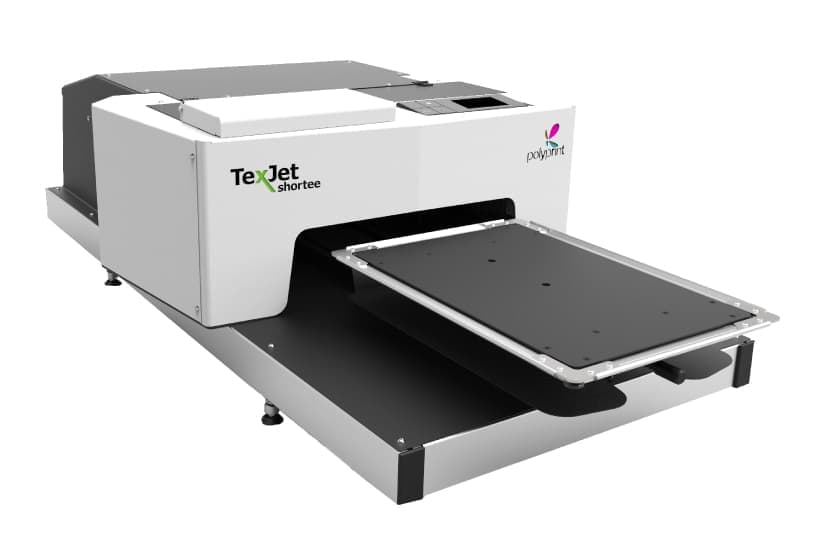

By opting for the TexJet® shortee, you get a DTG printer that produces quality prints on the go! Choose your location and set up shop wherever you need to print.

TexJet® shortee specs

Max Print Area 12.59×17.71in

Printable Textiles Cotton, polyester, cotton/polyester blends, linen, viscose, leather, and more

Print Resolution 720×720, 1440×720, 1440×1440 dpi

Multiple combinations possible (ie. 1440×1440 White x 720×720 CMYK)

Print Head Type Piezoelectric DOD, 8 channels, 180 nozzles per channel

Select the TexJet® more and get a DTG printer that not only prints on bed and table linens and towels, but can also print in two different areas at one time. That means you can have two print jobs running at once, increasing your productivity!

TexJet® more specs

Max Print Area 16.14×37.40in

Printable Textiles Cotton, polyester, cotton/polyester blends, linen, viscose, leather, and more

Print Resolution 720×720, 1440×720, 1440×1440 dpi

Multiple combinations possible (ie. 1440×1440 White x 720×720 CMYK)

Print Head Type Piezoelectric DOD, 8 channels, 180 nozzles per channel