It can be difficult to understand where your budget is going and how to effectively price your services. This blog will discuss many areas of a standard print shop’s business model and the screen printing cost breakdown. You’ll have a better understanding of each element of your business, but you’ll also be able to more effectively justify your pricing to customers while running an efficient shop.

Screen Printing Costs for All Print Shops

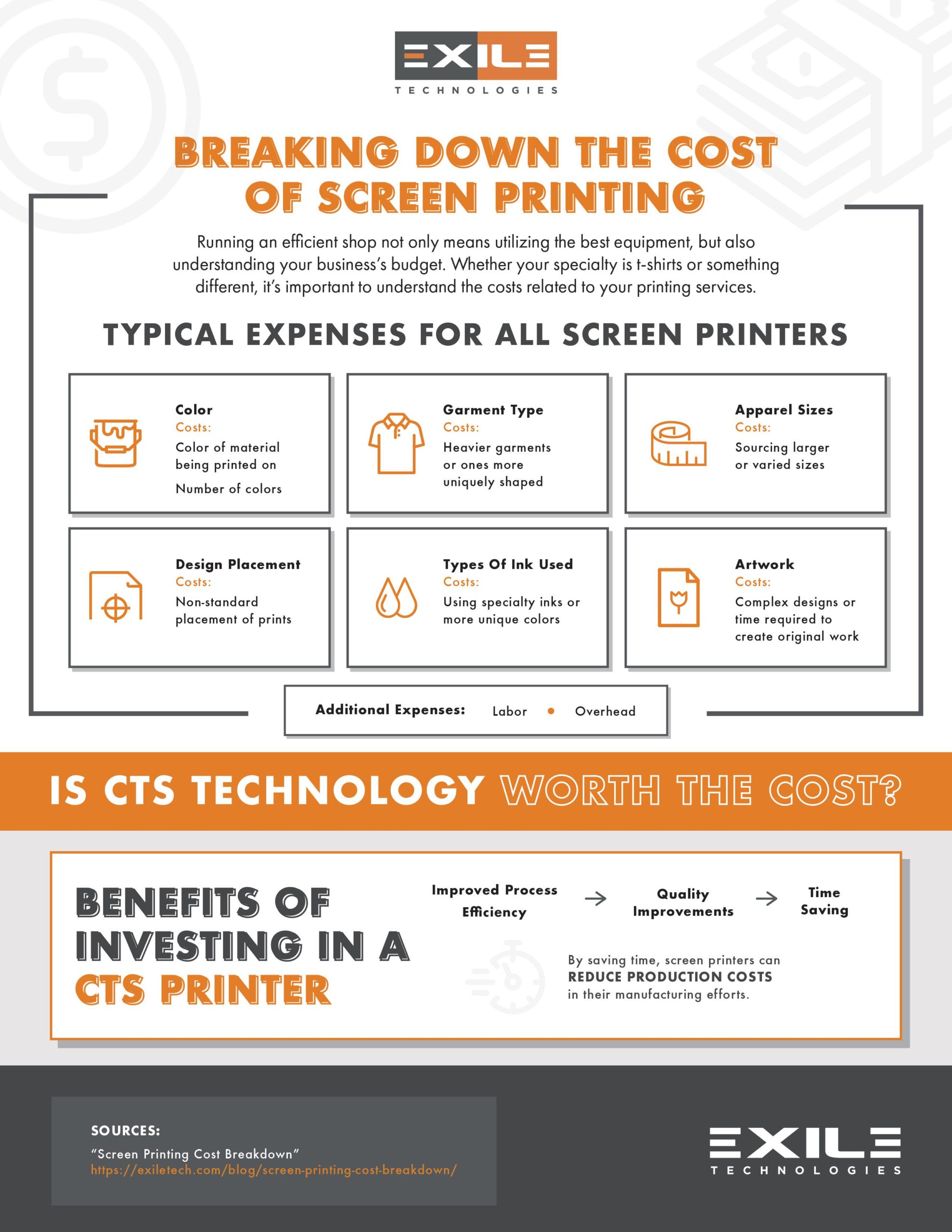

There are a lot of elements that play a role in the prices of screen printing services. When trying to establish standard rates for your print shop, it’s important to understand the costs of screen printing supplies, as well as decide how valuable your time and expertise is.

When looking at the screen printing cost breakdown for the average print shop, purchasing raw materials is a big expense. Whether you specialize in t-shirts or other print mediums, the supplies that you purchase are going to directly affect how you price your items. Check out this breakdown of things to consider for running a print shop:

Color

- Color plays two parts in determining the cost of a finished product: the color of the material being printed on, and the number of colors in the printed design. Because fabric gets more expensive the darker it gets, the cheapest option for a custom print material is white. Additionally, the more colors wanted for a design, the more expensive it will be. You will potentially consume more time separating your artwork, but you’ll also use more screens, more time in preparation, and more ink.

Type of Garment

- Most print shops deal in custom apparel, and some wearables are easier to print onto than others. Due to their flat, large surface area, t-shirts tend to be relatively easier to print on, reducing labor costs. However, heavier or uniquely shaped cost more to purchase. That means if a customer wants a hoodie, v-neck, or scoop neck t-shirt as opposed to a standard crewneck t-shirt, you’ll be spending more on both raw materials and press time.

Apparel Sizes

- Some print shops charge the same for all sizes, but the fact remains that it is more expensive to source larger sizes simply because they require more material to make. If you find that charging the same for all sizes is cutting into your bottom line, you might want to consider finding a supplier that does not charge more for larger sizes. This will make your pricing more inclusive and appeal to a broader audience.

Design Placement

- Standard placement for prints might be the center of the chest or back for a shirt, but designs on the arm require more skill and specialty accessories, warranting an upcharge.

Types of Ink Used

- Specialty inks or more unique colors cost more to source than standard colors like black, navy, white, or red.

Artwork

- Every print shop owner is familiar with the customer that comes in knowing exactly what they want their artwork to look like. However, they usually have no idea how much time a particular design will take to produce, or the skill required to translate it to a printable image. If the skill required is beyond your skill level, you may need to outsource a graphic designer who is an expert in designing screen printing artwork. Even if it doesn’t require outsourcing, your time is a cost that should be reflected in the price.

Other Print Shop Expenses

Additional expenses for a screen printing business are labor costs and overhead costs.

Labor costs

- As with any business, running a print shop requires hiring staff members that know what they’re doing. Even the smallest print shop may have a handful of employees to keep things running smoothly. If you are looking to cut down on labor costs, CTS printing can help save time by speeding up your manufacturing and help your employees work faster.

Overhead costs

- Overhead costs might include storefront rent, insurance, and other utilities. These are typically subject to change year by year, so it’s important that you always try to get the best rate for better cost savings in the long run. A CTS machine not only gives the added benefit of efficiency, but can potentially save you space, which may allow you to rent a smaller storefront to save on overhead costs.

The Benefits of CTS Technology for Print Shops

If you are one of many large or small businesses thinking of investing in a CTS printer but are wondering if it’s worth the cost, take the leap! Most shops notice immediate improvements in their production process after introducing one or two CTS machines to their shop.

With a single screen printing tech, you can:

- Take out a freshly printed screen

- Put that screen into an exposure system, such as the V-Lux, and start the exposure process

- Put a new screen in the CTS Printer

- Hit Print

- Pull the exposed screen from the V-Lux Exposure unit

- Wash out the screen

- Set it up to dry

- Go back and repeat the process.

This process can potentially allow zero downtime in the screenroom, speeding up your processes and saving you time. With proper training and practice, your production crew will be able to use the CTS printer to cut out unnecessary production steps. Time is money, and this efficient technology will help you reach your cost saving goals. With a CTS, it’s all about buying time.

Shop CTS with EXILE Technologies

Computer-to-screen printing is ideal for those looking to improve the efficiency and productivity of their business with automation. Our computer-to-screen solutions offer our customers a variety of choices and configurations to meet the needs of each shop’s environment while saving time. If you are looking to figure out how to utilize this screen printing cost breakdown to reduce production costs in manufacturing, you won’t find better technology or more reliable customer service anywhere else. Contact us today for more information on our products and financing options.