Storing your film positives is an essential part of running your business, and there are too many ways to count how they can become damaged if not properly stored. But what’s the best method for screen printing film storage?

No need to scour the internet or skim the forums. We condensed information on how to keep your films lasting for years. Read on to learn more.

Why Is It Important to Store Films?

Many companies want to reuse film positives if a client re-orders a print since reprinting will cost more time and money. If you think saving time and money seems a reasonable effort, properly storing your films for repeat jobs becomes essential. Otherwise, it is likely a moot point.

Film is a flimsy material that is easily damaged; it is prone to fading, susceptible to contamination and damage due to handling and storage, and some of the more common films are impacted by the environment. Inkjet film is also inclined to transfer ink to material with which it is in contact, both while in use and while in storage.

Depending on the material of your film, you will also need to ensure that it is kept dry and won’t be exposed to any water or moisture. There are, however, water-resistant transparent films that can help you eliminate this worry.

Methods for Film Storage

Since we know that film positives are susceptible to damage, it’s important to know how best to store them and how to keep your film storage effective and efficient. After all, your business workflow is a priority for serving your customers.

Some common resources are Uline Jumbo Kraft Envelopes, since they can incorporate big sizes, and they’re great for not scratching film positives. We recommend storing them in a vertical position in an organized box. This is essential because if they’re stacked together, they have a tendency to eventually meld together.

There are also many DIY approaches to creating a storage system for your film positives. You can hang them in kraft envelopes on a string with binder clips. Some screen printers also use coat hangers, clothespins, flat file cabinets, and traditional filing cabinets.

It’s also been suggested that X-ray folders and cabinets work well for storing your screen printing films. You can find these online or at an office supply store. You may also be able to find some from a local medical supply company. One method is utilizing Smead 66300 PXR7 X-Ray Jackets with Pockets and then storing those jackets in a Rubbermaid container box.

Another industry that has a useful tool for screen printers is architecture. Flat files with folded sheets of large paper can be utilized as folders, and while they can be expensive, you may be able to find them at a discounted price on resources like Craigslist.

If you can’t find a kraft envelope in the size you need, some businesses also utilize storage tubs for larger films. We advise testing this before making it a practice since the films are still susceptible to damage using this method.

EXILE Technologies Saves You Time

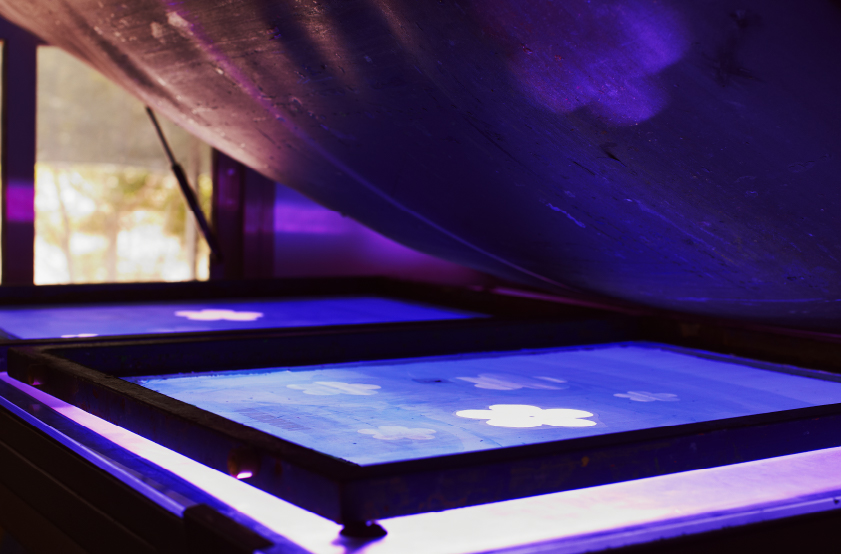

If you find these different storage options tedious, ineffective or take up too much space, there is another solution. EXILE Technologies offers a wide range of thermal imagesetters, direct-to-screen printing systems, and printing solutions to meet all of your printing needs. Our products are guaranteed to save you time and space!

The thermal imagesetters available at EXILE Technologies produce a film on thermal film, which is highly durable, leaving you worry-free about damage. Our thermal imagesetter is available in various sizes and resolutions and ensures they fit your film output needs.

We have a line of computer-to-screen (CTS) printing systems that automate the digital prepress process. This means you do not have to worry about screen registration or having the resources and space for film storage. The CTS imaging system eliminates any need for the film while also reducing labor and overhead costs because it takes a fraction of the traditional time to accomplish the same results. This method also allows screen prints to consistently come out at a higher quality.

EXILE Technologies has been the leading manufacturer of imaging solutions for over 30 years. We specialize in applications of screen-printing technology, flexography, and pad printing. Whatever your shop size or your production needs may be, we have a product for you.

We also understand the need to weigh the advantages and disadvantages of incorporating new methods into your workflow. That’s why our experienced staff members are available to speak to you about your printing needs, and they can help you decide between our different models in our demonstration rooms.

Contact us today for more information.