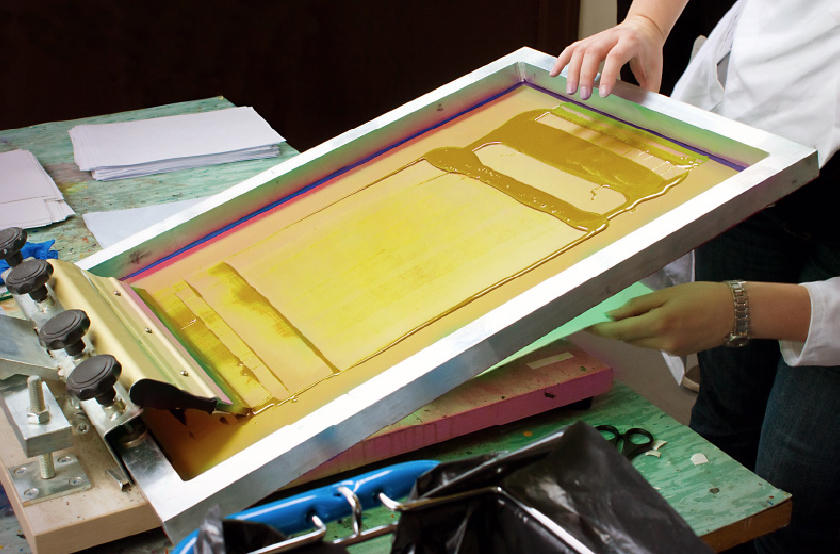

As with most things, perfecting the art of screen printing is a constant endeavor. Even those who have been in the industry for years will admit to making screen printing mistakes that cost their business both time and money. And, while mistakes can happen no matter how diligent you are, it remains important to do your best to avoid them. Keep reading to explore some of the common mistakes screen printers make and to learn about ways you can avoid them.

Common Screen Printing Mistakes

Registration issues

- Registration is the process of making sure elements of your print align. There are various methods you can use to yield the best result, but ultimately, it’s easy to make mistakes if you aren’t using computer-to-screen (CTS) technology. EXILE’s Spyder CTS features registration systems that provide extremely accurate placement of the image from color to color, screen to screen. Once paired with the registration system, it produces a more efficient and mistake-free result.

Image quality issues due to film

- When using traditional methods to create screens, issues with poor image quality related to the film used are common. If there are issues with the film quality used in creating your screens, exposure can be poor and bad screens will be produced.

Not measuring exposure time

- One of the first problems people face when learning screen printing techniques is learning how to expose the screen properly. This largely has to do with the emulsion you use; getting an exposure calculator will tell you how long you need to expose your screens.

Not using off contact

- Keeping a bit of a gap between the screen and the substrate, so it doesn’t stick together as you push and pull the ink, will help improve image quality.

Not performing a test print

- Even an experienced screen printer needs to do a test print, but many often try to forgo this important step. Doing a test print using screen printing test pellons before committing to it can help ensure the desired result.

Human error

- The biggest mistakes that occur when screen-printing can usually be attributed to human error. Because no one is perfect, investing in CTS technology for your screen printing shop is one of the best ways to reduce many human-related screen printing mistakes.

Best CTS Technology for a Print Shop

Because most print process mistakes are a result of human error, it may seem impossible to get consistently error-free finished products. However, with CTS technology, you can remove the opportunity to make mistakes by automating your processes. CTS produces first-generation artwork because it doesn’t use film positives, eliminating many quality issues introduced in the exposure process. Here are some CTS machines that make excellent additions to any screen printing business:

Spyder CTS

Simplify your pre-press workflow with EXILE’s industrial Spyder III computer-to-screen system. The Spyder III saves you time and money with its ease of use, superior throughput, and precise registration systems, delivering a boost in production and accelerating job turnaround. Equipped with a fast and reliable RIP software, full user control over your screen printing process is provided to create unparalleled prints with exceptional detail.

V-Lux

The unique vertical design of the V-Lux Exposure unit allows for simple and easy loading and unloading of a screen, using integrated rails to maintain the proper exposure distance from the LED light source. The unit is built with computer-to-screen in mind and, when combined with EXILE’s Spyder system, ensures high-quality results.

EXILE Technologies

At EXILE Technologies, we are committed to providing high-tech solutions to screen printing challenges. For over 30 years, we have been leaders in manufacturing imaging solutions, specializing in products and support services on a global scale. If you are interested in upgrading outdated equipment and investing in CTS technology for your print shop, contact us today.