Once your t-shirt printing business has grown and you’ve established your reputation, there eventually comes a time when clients begin bringing you more complicated prints. It is inevitable. When you find yourself in this position, simulated process screen printing, commonly referred to in the industry as “sim process”, is a great way to offer more colorful and complicated designs. This is the preferred method for printing detailed images that are rich in gradients.

Keep reading to learn more about this process and how it can be beneficial to your business.

How Does It Work?

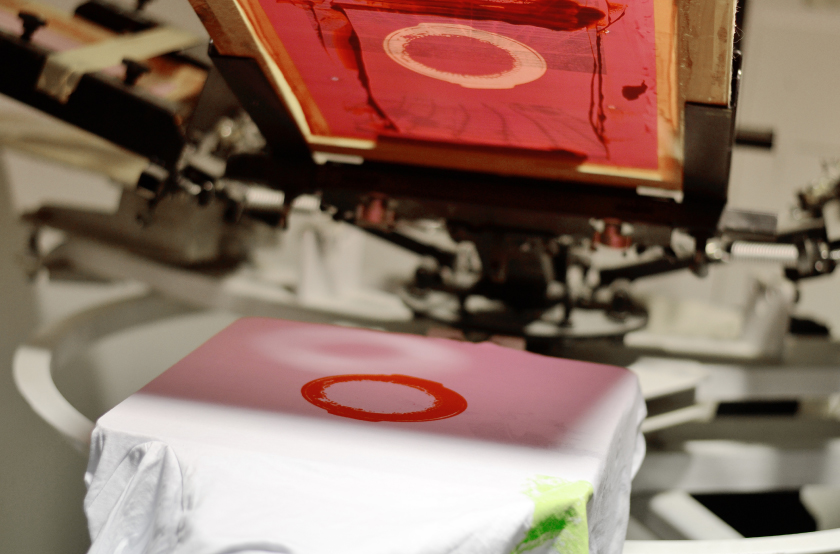

Simulated process printing works by printing halftone dots to create detailed images with diverse colors. Similar to CMYK, the small half-tone dots are used to blend colors and to print extremely detailed, intricate imagery. To create different colors, the halftones overlap and the individual ink colors blend together. This technique is popular for producing punchy, colorful, images and designs onto wearables like t-shirts, hoodies, aprons, hats, and more.

What Are the Benefits of Sim Process Printing?

Over the years, several methods of printing have been employed. But what makes simulated process printing preferable to cyan magenta yellow and black (CMYK) and spot color?

Spot Color Printing

- Spot color is the most commonly used color printing technique. These designs are generally created by using vector graphics to create designs that are printed as solid shapes as well as half-tones. They are great for single and multi-color designs where no color blending is required. This technique produces vivid colors, clean edges, and allows for exceptional color control. However, this method does not work for photographic or complex blended designs.

Four Color Process Printing

- This technique is the oldest color reproduction printing method. It is traditionally referred to as Four Color Process printing, where colors are created by building a dot centered rosette of these four colors of ink, cyan, magenta, yellow, and black. This process has been and continues to be used in offset, flexographic, and graphic screen printing.

- Due to angle conflicts with mesh, and the weave of shirt materials, this is no longer a widely used method in t-shirt printing. The cons of this technique are that the user needs

- to have an expansive understanding of mesh selection, screen angle sets, and the problems the incorrect selection will cause, and a solution to resolve them.

- While it may be less expensive to produce colorful prints in terms of using colors, and therefore, fewer screens, the process just does not deliver consistent image quality on shirts. This method’s reduced color pallet makes it more difficult to make that vibrant and colorful design. In addition, registration is incredibly important to the process otherwise color shift will be problematic. It should also go without saying, but we will anyway, using this method, printers will be unable to reproduce certain colors.

Simulated Process Printing

- Although many print shops get by using only spot colors, simulated process printing can expand your customer base. Like CMYK, but without the dot centered rosette, this method works by overlapping and blending colors. Using multiple and bright colors, simulated process creates a reliable, vibrant, and production-compatible ink set that can be used to print virtually any color or design on any kind of garment. This method has become increasingly prominent in high-end color printing and typically results in fewer misprints. There are plenty of software applications or plug-ins that help produce the separations. However, as with any new skill, the user needs to thoroughly research the method and practice it before using it in their shop.

- This method creates highly-detailed graphics with the flexibility to print on any colored garment. Many may find the need to educate themselves on the process off-putting, but nothing worth having comes easily! If the learning curve is too frustrating, there are a number of specialists in this industry who offer training or whose separation services are available. Whether you choose to outsource this service, or put in the work required to master this technique, you open the doors for your print shop to create more complex work and achieve a larger base of satisfied customers.

High-Quality Printing with EXILE Technologies

Printing is a skill that many entrepreneurs and businesses can utilize to reach their goals. If you are a printing business or are interested in doing your own printing, then a quality print job should be your number one priority. At EXILE Technologies, we make the search for state-of-the-art printing equipment easy. From services to supplies, everything you need to start producing high-quality prints is right here. Contact us today to learn more about simulated process screen printing!