Well, there is no such thing as pre-press printing. There is pre-press, and there is printing. Pre-press is just what it says, everything before the press, and a lot has changed in pre-press since Johannes Gutenberg’s printing press in the 1400s. Technological advancements continue to improve the printing industry every day! Digital pre-press technology has boomed in the global market, and industry experts predict that the growth will only continue to rise.

But what exactly is pre-press, and what is involved in its digital automation? Our team has assembled the answers into the following article.

What is Pre-Press?

Pre-press is the industry term for the preparations made after a printing shop receives an order with a graphic file but before any printing is completed. It involves creating a print layout and all other steps needed for a print company to complete the final print project.

Steps to the Pre-Press

Once a client or a graphic designer hired by the client submits an art file for the printer, the pre-press has begun. The graphic files will typically be delivered in an Adobe InDesign format or high-resolution PDFs, and the pre-flight will start the pre-press phase.

Pre-Flight

Pre-flight is when the art file’s data is validated to ensure it meets all production requirements. Examples of these requirements include ensuring the graphic has the proper format and resolution, all required fonts are included, PMS/CMYK colors are properly set up, crop marks and bleeds are up to standard, and many more small considerations that the printing company makes to ensure that nothing will go wrong in the printing process.

The pre-flight stage in pre-press also sometimes requires converting files to be better suited for commercial printing. This is the time to find mistakes and correct them to make sure the art file is ready for printing.

Proofing

Once all of the data is validated in the pre-flight phase, many shops will create a proof, which is a close representation of how the final print will turn out. The industry standard is to create a proof as a PDF to send off to the client for approval, not only to ensure client satisfaction but also to speed up the process. Printing projects that involve binding, folders, or other finishings will require that the printing company presents a physical proof to the client.

Printing

Once the client approves the proofs, the project is ready for print production.

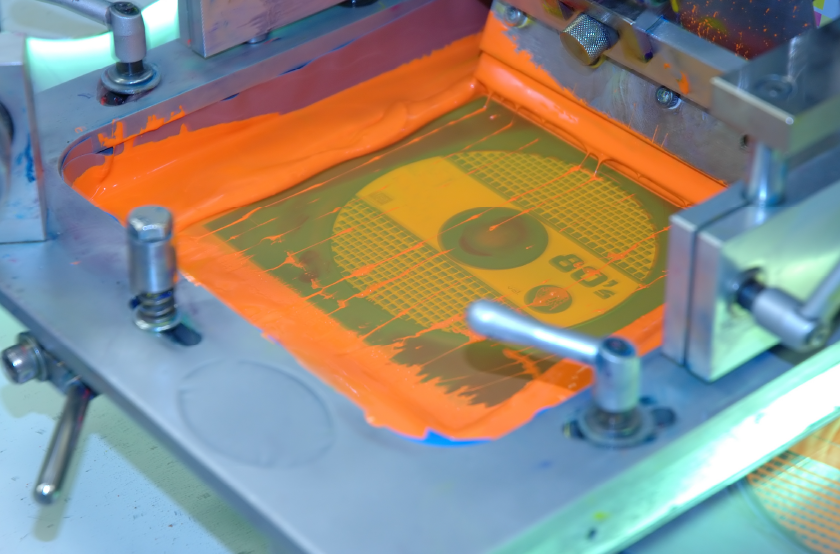

This applies to nearly all printing segments. Whether you are utilizing offset printing, flexographic printing, or screen printing, plates or screens will need to be created to provide a method for transferring the inked image.

In today’s work, much of the electronic pre-press process has been relegated to “direct-to” or “computer-to” technologies. For both offset and flexo, “Computer-to-Plate” is the standard these days, but there are huge differences in the technologies for offset and flexo. Even screen printing has found a “computer-to” in Computer-to-Screen (CTS) technologies.

In many instances, your printing company could also utilize a thermal imagesetter for film, whether in corrugated flexo, low-end narrow-web flexo, or screen printing. This technology does not require any toner, inks, chemicals, or processor. The great thing about imagesetters is that they can be used anywhere!

If you don’t want to hassle with film-in screen printing any longer, computer-to-screen (CTS) printing technology is your best, most efficient solution.

How to Get Exceptional Print Results

There is no doubt that the pre-press stage is essential in a print company’s production, but your team can work together more efficiently and effectively with the innovative pre-press solution from EXILE Technologies. Our company offers some of the best technology in the printing industry—thermal imagesetters, direct-to-screen systems, and printing solutions to meet your printing needs.

Our Spyder II and III simplify the pre-press process with an incredible computer-to-screen system with its superior throughput and precise registration system. The V-Lux allows for easy loading and unloading of screens, and it exposes the screens quickly using UV-LED technology. When either of the Spyder models and the V-Lux are paired together, your company will have a boost in production and accelerated job turnaround that provides unparalleled prints with exceptional details to clients.

We also offer firsthand looks in our demo area to ensure our equipment is what your screen printing business needs. Contact us today to get more information!