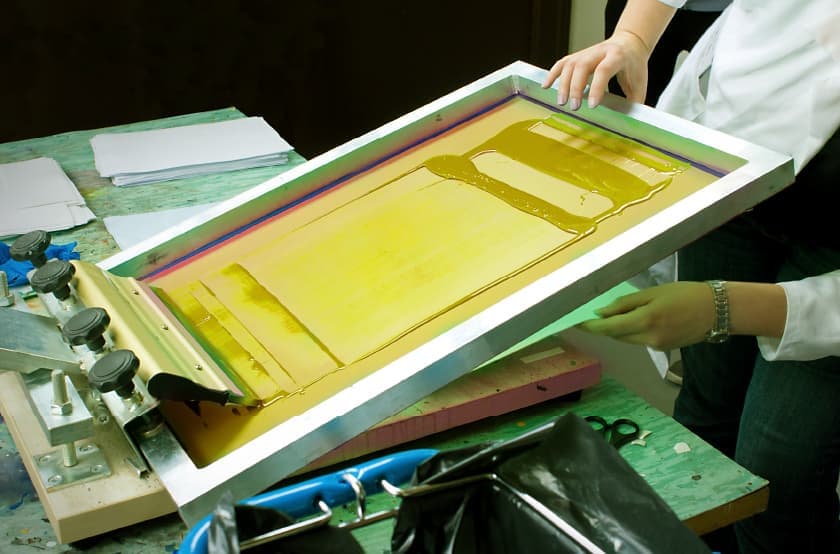

For every screen printing shop, the quality of the screen is significant to the quality of the product printed. Knowing how to clean, store, and care for your screens and frames helps maintain the maximum life of this crucial component and improves your print quality and your productivity. If you are taking proper care of your screen printing screens you will not have to replace them frequently.

Below are some tips to help you maximize the life of screen printing screens.

- Invest in the Best Screens and Frames

- Know How to Perform Proper Screen Maintenance

- Reclaim Screens Properly

- Spotting the Signs of Aging

Invest in the Best Screens and Frames

Getting the most out of your production usually means buying quality tools. When it comes to screen printing, this means investing in quality frames and mesh. When trying to keep your cost of operation low, buying low-budget frames is tempting, and may seem ideal. However, like most products, when buying frames and mesh, you ultimately get the quality that you pay for.

Know How to Perform Proper Screen Maintenance

This is your investment, be interested in how to clean and maintain your screens. If you need more information on how to and troubleshooting techniques, here are some other blogs that we have written that will help:

Reclaiming Screens Properly

Making sure that you wash screens quickly after production finishes. This will stop the ink on the screens from drying, which will, in turn, make the reclaim process easier. You should let the emulsion soften with emulsion remover. Use the lowest setting on a pressure washer to rinse out the chemicals. Using a less aggressive reclaim process will assist in increasing the screens’ longevity and keep it useful for multiple, quality production runs.

Spotting the Signs of Aging

An expired or “overused” screen may be twisted or bent. Retensionable frames may be loose. One of the most noticeable signs of aging and wear will be a loss in mesh tension. Changes in mesh color and signs of “ghosting” effects that cannot come off are also indications of a need to replace, refurbish, or re-mesh your frame and possibly exchange the frame. Being aware of the signs and identifying exhausted screens will help you maintain a higher quality product coming out of your shop.

A print shop using computer-to-screen equipment will definitely want to follow good screen maintenance. In this case, since the screen is also being used as a print surface it needs to be in the best condition to ensure good print quality. Defects such as torn or repaired mesh, excess emulsion or other imperfections can negatively impact the final print.

Screens are one of the most valuable, and given the number of screens often kept on hand, they are one of the costliest items of a screen printer’s budget. They should, therefore, be able to be used for multiple jobs, and the frame kept for years.

- Know how to handle screens and mesh.

- Store your screens in a clean and dry place in your shop.

- Follow and establish a practical screen maintenance routine

Keeping to these simple guidelines will help you maximize the life of your screens.

Stay in touch for more useful tips and blogs for operating your shop. EXILE Technologies has years of pre-press and printing experience. We are here to help where we are able.